Prototyping and small series

Saint Jean Industries develops its prototypes internally with several possibilities according to the quantity of parts to be realized. It is adapted to very small series in order to be able to model parts, test them, and obtain pre-production results.

Sand casting

This process consists in pouring molten aluminum or steel in a sand mold whose shape is obtained thanks to an impression. Saint Jean industries uses it to obtain complex and hollow parts for small and medium series.

The advantages:

- Good dimensional accuracy

- Allows the realization of complex parts

- Perfectly adapted for prototyping, small and medium series

This casting process is particularly suitable for motor parts such as electric motor housings, power electronics housings, stator or rotor, suspension arms and hollow pivots…

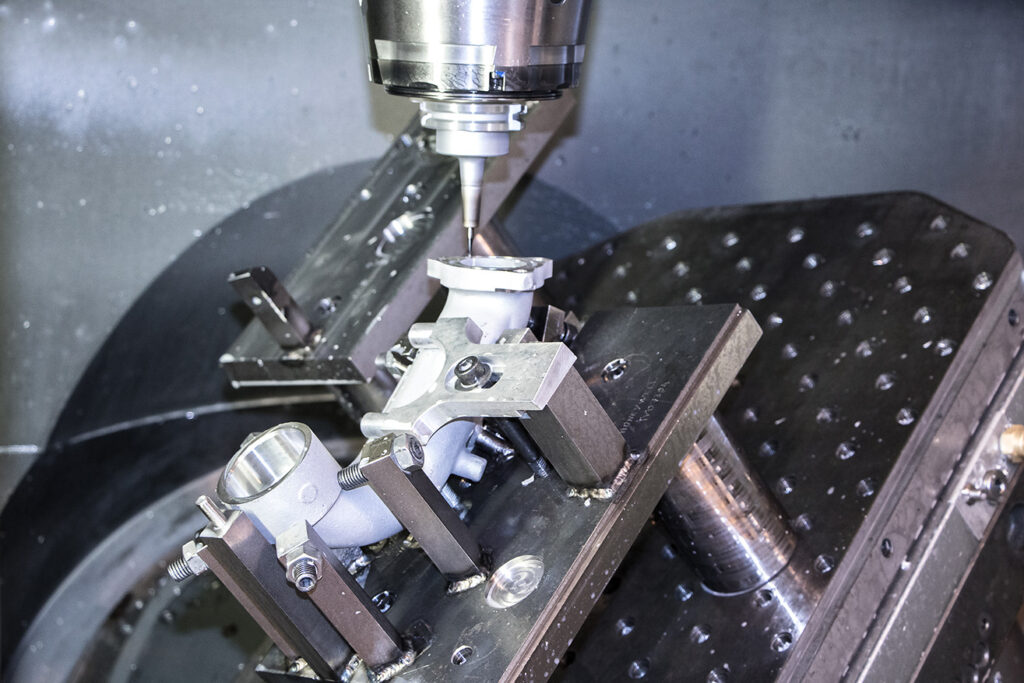

machining in the mass

This prototyping process consists in machining a part completely in a block of material. Saint Jean Industries uses it on all types of materials for very small series.

This process is suitable for unit or small quantities (> 1000 pieces) with relatively short lead times.