Aluminium welding and assembly line for the prototype production of battery trays and modules structure to go in production.

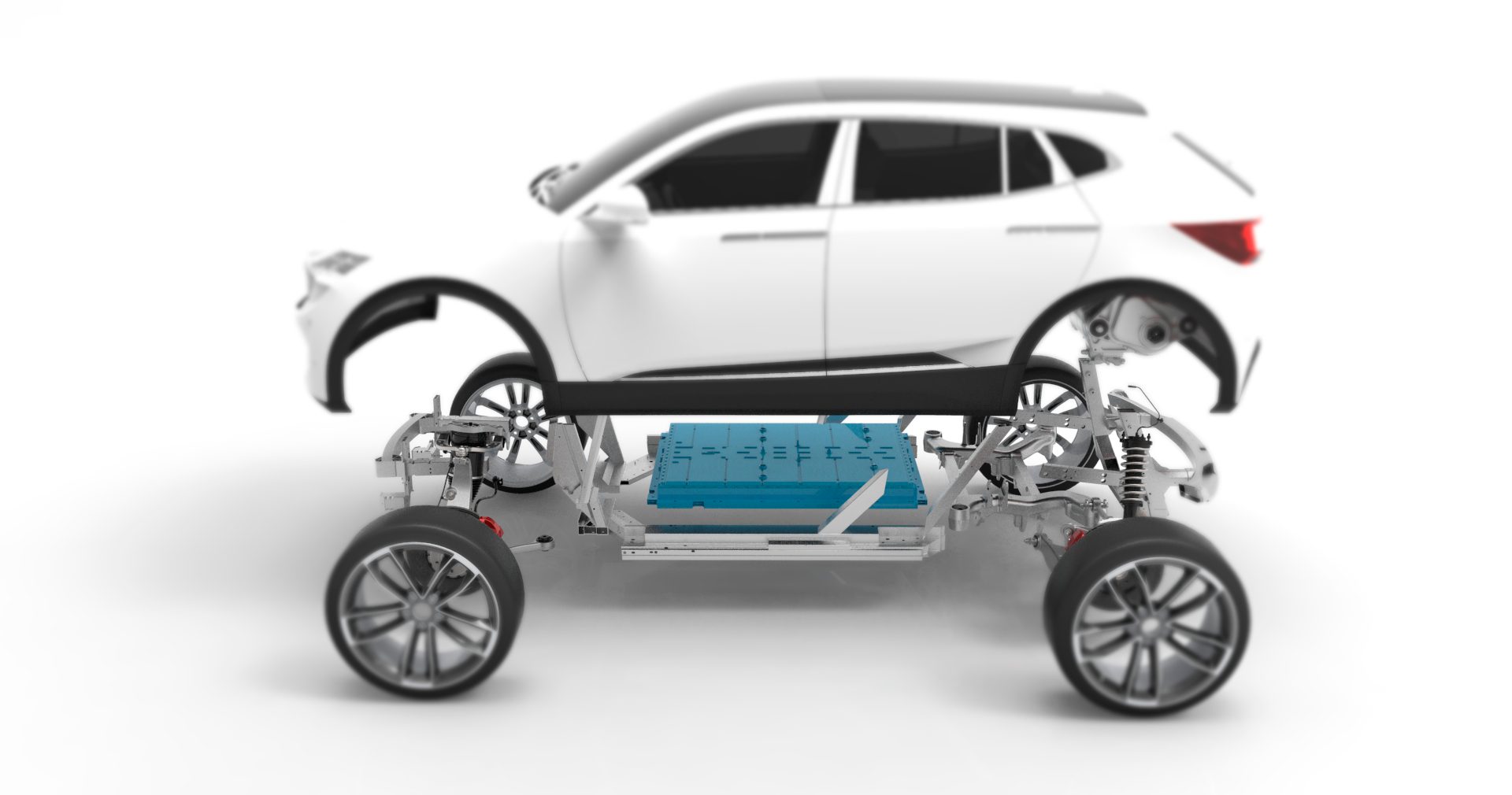

Ilsfeld 16.12.21 – Saint Jean Industries Stuttgart GmbH is upgrading and further expanding its commitment to electric mobility. A new production line is specifically designed for the prototype production of battery trays and modules structures, and subframes in aluminium hybrid construction. The setup of such a production line is another milestone in the company’s consistent orientation towards the needs of e-mobility.

The Saint Jean Group as a chassis and aluminium lightweight construction specialist from France and Tier 1 supplier with 9 plants worldwide in Europe, the USA and China has already been active for over 30 years. With its existing production capacities, Saint Jean Industries Stuttgart GmbH, located in the immediate vicinity of Heilbronn, is able to produce battery carriers with dimensions of up to 3,000 mm in length at short notice.

In the production line, the extruded profiles machined in-house are further processed with all types of castings, including those from the Saint Jean Industries Group, and finished by means of welding, bonding and the latest joining techniques to form the subassembly into the ready-to-install solutions. The prefabrication of subassemblies is carried out by a new robot welding cell that is specially designed for this purpose. The additional welding capacity helps to shorten the throughput times for the prototypes and increases the production capacity in this area.

At IAA 2021, several vehicles were already presented whose battery trays and modules structure came from the prototype line of Saint Jean Industries Stuttgart GmbH. Apart from accomplished passenger vehicles, production is currently underway for vehicles from the commercial vehicle sector.

At the Ilsfeld site, which was founded in 1992, Saint Jean Industries Stuttgart GmbH produces assemblies in aluminium lightweight construction for the automotive industry. The focus is on battery trays, modules structures, subframes and safety-relevant assemblies for the crash areas of vehicles in series production. In principle, series of 1 – 50,000 vehicles per year can be produced, and even more depending on the project. Customers include a number of well-known OEMs in southern Germany, but also various sports car manufacturers in the immediate vicinity as well as in Italy and England.