COBAPRESS™ technology is perfectly suited to the needs of lightweighting, mechanical strength and design freedom of ground connection parts. This process solely owned by SJI is now recognized worldwide for its unique mechanical characteristics.

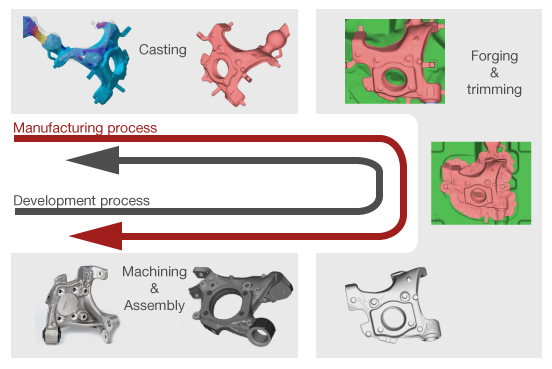

The COBAPRESS™ Hybrid Process involves forging a foundry preform. It has already produced more than 100 million parts for automotive manufacturers worldwide.

Better material health E155 ASTM standard < 1

Stable process allowing frequency control in series.

Great freedom of design allowing the lightening of the parts.

Elimination of internal defects and optimization of mechanical properties.

Excellent fatigue resistance thanks to the skin effect.

Recyclable alloys integrated into the process

Reduction of material waste

Realization of complex shapes thanks to greater design freedom

Great freedom of design allowing the lightening of the parts.

Two innovations at an advanced stage of maturity are being offered today:

COBAPRESS™ is particularly suited for safety critical parts such as suspension and chassis parts: stub axles and wheel carriers, control arms, shock fork, clevis, bi-material brake disc, suspension mount.