FLOW FORMING

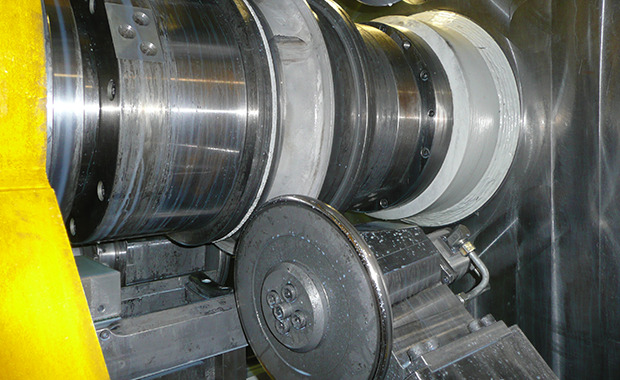

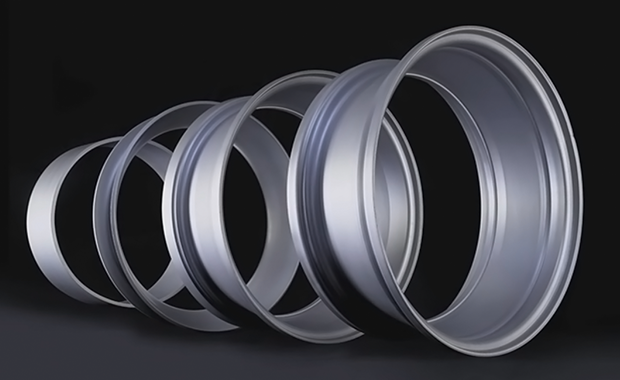

Flow forming is a process of plastically deforming metals by extrusion. The material flows between a mandrel set in rotation and a wheel exerts a high pressure in the axial direction. It allows to obtain cylindrical forms of low thicknesses as for example the aluminium rims proposed by Saint Jean Industries.

Previous

Next

The advantages of cold flow forming

- Reduction of thicknesses.

- Improvement of mechanical characteristics.

- Applicable for small or large series.

- Excellent dimensional accuracy

- Material saving

- No lubrication

- Reduction of machining

- Very good surface finish

our Aluminium processes

Our cobawheels™ process

COBAPRESS™

This process offers great design flexibility, improved mechanical characteristics, and very good fatigue resistance

Flow forming

A process commonly used in the manufacture of cast aluminum rims, Saint Jean Wheels applies it to an extruded tube to lighten the rim bed.

Friction stir welding

Used to weld the two parts of the rim, without adding metal, whatever the alloys used